1, vertical crack seepage

Expression form: after basement main structure construction, the central area of reinforced concrete wall and the side of retaining wall column appear vertical crack, and there is water leakage phenomenon.

Formation reason: waterproof concrete did not use low hydration heat cement or did not add anti-cracking fiber and expansion agent, premature disassembling and poor maintenance.

2, construction joint water seepage

Expression form: basement deformation joint and construction joint new and old concrete connection along the gap water leakage phenomenon.

Formation reasons: basement warehouse is too large or deformation joint, construction joint location is not reasonable, construction joint interface treatment is careless or with pressure water pouring.

3, floor cracks seepage

Form of expression: basement floor cracks and water leakage phenomenon.

Formation reasons: concrete vibration is not dense, floor thickness is not enough or span is too large, or building settlement is too large, resulting in floor reaction is too large, anti-floating pile and bolt design is unreasonable.

4, roof cracks seepage

Expression form: basement roof appears regular well shape block crack and leakage phenomenon.

Cause of formation: basement roof thickness is not enough or too thick, concrete mix ratio and material are improper, vibration is not dense and bad maintenance, the roof of the soil covered with hollow floor cover.

5, roof wire box seepage

Expression form: basement roof line box or line pipe seepage.

Formation reason: basement roof wire box, wire pipe layout is unreasonable, wire box position reinforcement is not strengthened. There are stowed or heavy haulage passages on basement roof that have not been reinforced.

6. Water seepage around the tube

Expression form: embedded casing and directly buried pipeline through waterproof concrete wall leakage phenomenon.

Formation reason: the wall bushing is not welded water stop ring or the size of the water stop ring does not meet the requirements, the welding quality of the water stop ring is poor.

7. Water seepage around bolts through the wall

Expression form: external wall and pool wall through the screw seepage phenomenon.

Formation reason: through the wall screw water stop ring size is too small or not full welding or welding is not full, premature dismantling of the screw surrounding concrete is disturbed.

8, water seepage prevention and control measures

For underground engineering structures, water seepage is inevitable due to the differences in design, construction and maintenance, as well as the existence of capillary pores and micro-cracks with widths greater than 0.2 mm. In fact, the denser the concrete, the stronger the suction of the pores, the farther the penetration distance. The root causes of water seepage, damp and mildew in underground works are:

1) The underground water enters the inner side of the concrete structure through the siphoning effect and cracks of the pores and pores, resulting in water seepage and moisture.

2) After the water molecules in the air contact the wall and ground surface, due to the temperature difference, there will be condensation, moisture return and mildew problems, especially in the summer rainy season.

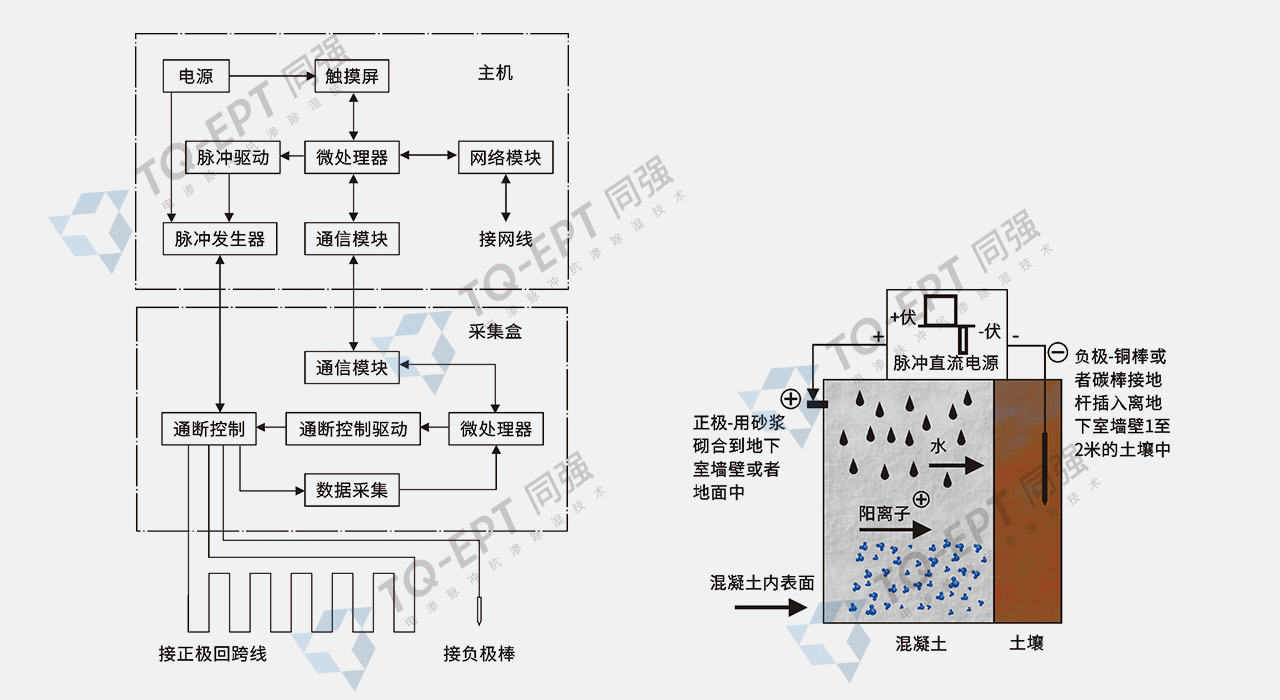

According to the above problems, Changsha Tongqiang electronic technology Co., Ltd. suggests the use of international leading underground engineering seepage control dehumidification special technology - - electroosmotic pulse anti-seepage dehumidification technology, completely eradicate the seepage, moisture, condensation and mildew problems of the basement. The technology has been successfully used in foreign markets for more than 30 years; After this technology was introduced into China at the beginning of this century, a set of anti-seepage and dehumidification technology for underground structure suitable for China has been formed through various stages of digestion, absorption, transformation and expansion. In recent years, it has also been applied to the repair of degraded concrete.

In view of the damp, leakage and mildew conditions of the building, our company has developed a set of comprehensive dehumidification overall solution:

Tq-ept electro-osmotic pulse structure anti-seepage dehumidification system products + air dehumidification system products + environmental protection anti-mildew pretreatment scheme