The scene was a little dirty:

A letter of apology for our late arrival

To some extent, those who click into this article are friends who really care about their peers. But I'm sorry, this is a public apology letter from XiaoQ on behalf of all the staff of Tongqiang Technology.

It is a good thing that sales results are reported frequently, but during the project in full swing, Small Q received feedback from customers: our construction site is not clean enough.

不找借口

别把“被误解”当做甲方的宿命

Reason for apology:

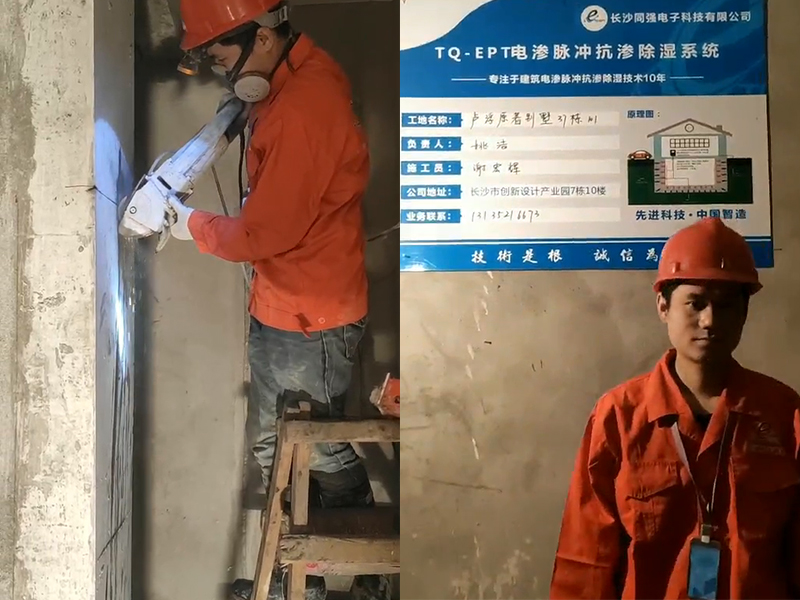

Our construction site has water, resulting in the construction environment is not clean and beautiful.

Causes of the problem:

Dirty construction environment: the main reason is that we chose the wet operation mode of water slotting, and the engineering team failed to explain the reason to the customer after the completion of the operation.

Solutions:

① The Marketing Department made a statement and made a public apology;

② The construction process of the engineering department should be standardized, and the management of regular training and assessment system should be strengthened.

After figuring out what happened, Xiao Q explained to the customer and got the understanding at the first time.

There are no small things when it comes to questions raised by customers. Q has the responsibility to explain to all the friends who care about us -- the reason why we choose water slotting.

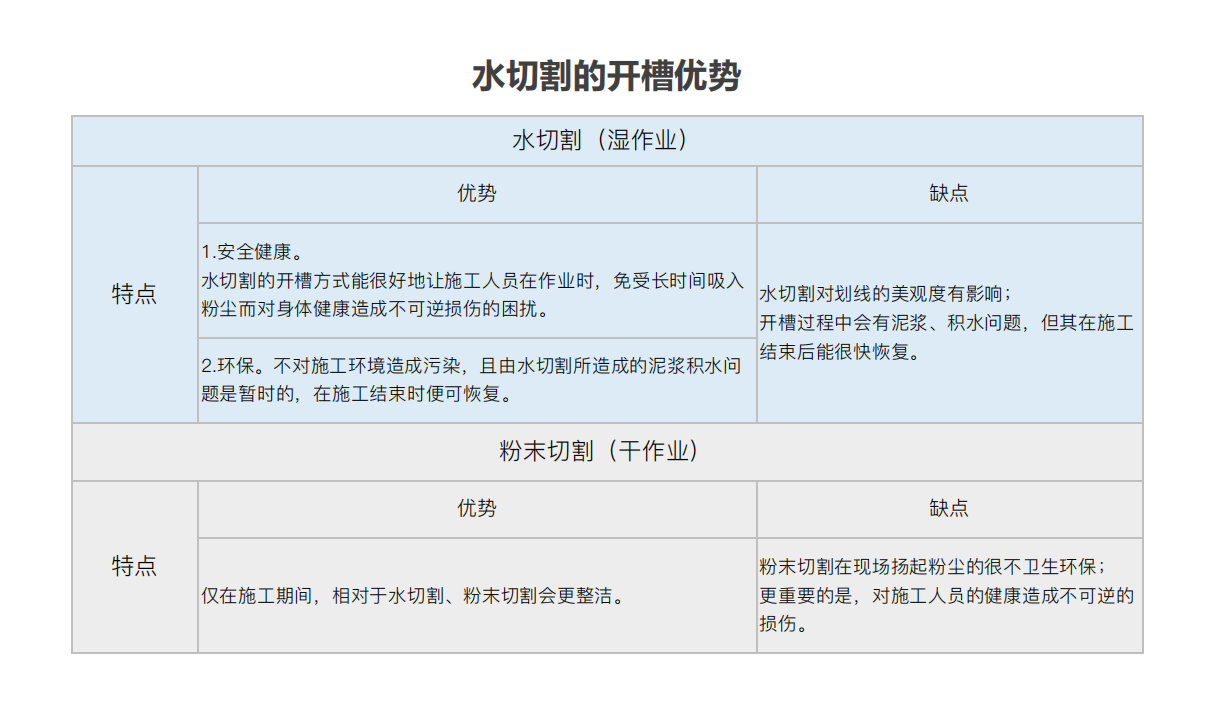

In the process of construction, slotting is an essential part of the process, slotting can be divided into two kinds of dry/wet operation:

Choose dry operation, that is, the advantages of powder cutting are obvious: it is easy to operate, line neatly, the construction environment is relatively cleaner. So it is not wrong to get more engineering side of the favor;

△Powder cutting site△

△Powder cutting site△

And wet operation, that is, water cutting is not so convenient: water cutting is more difficult to control, the beauty of the line will also have an impact, the environment is also very "bad"……

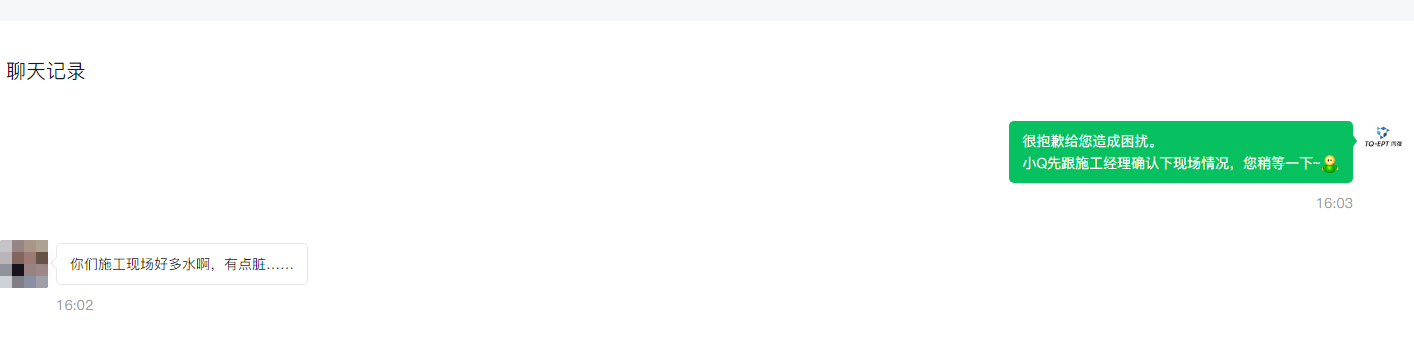

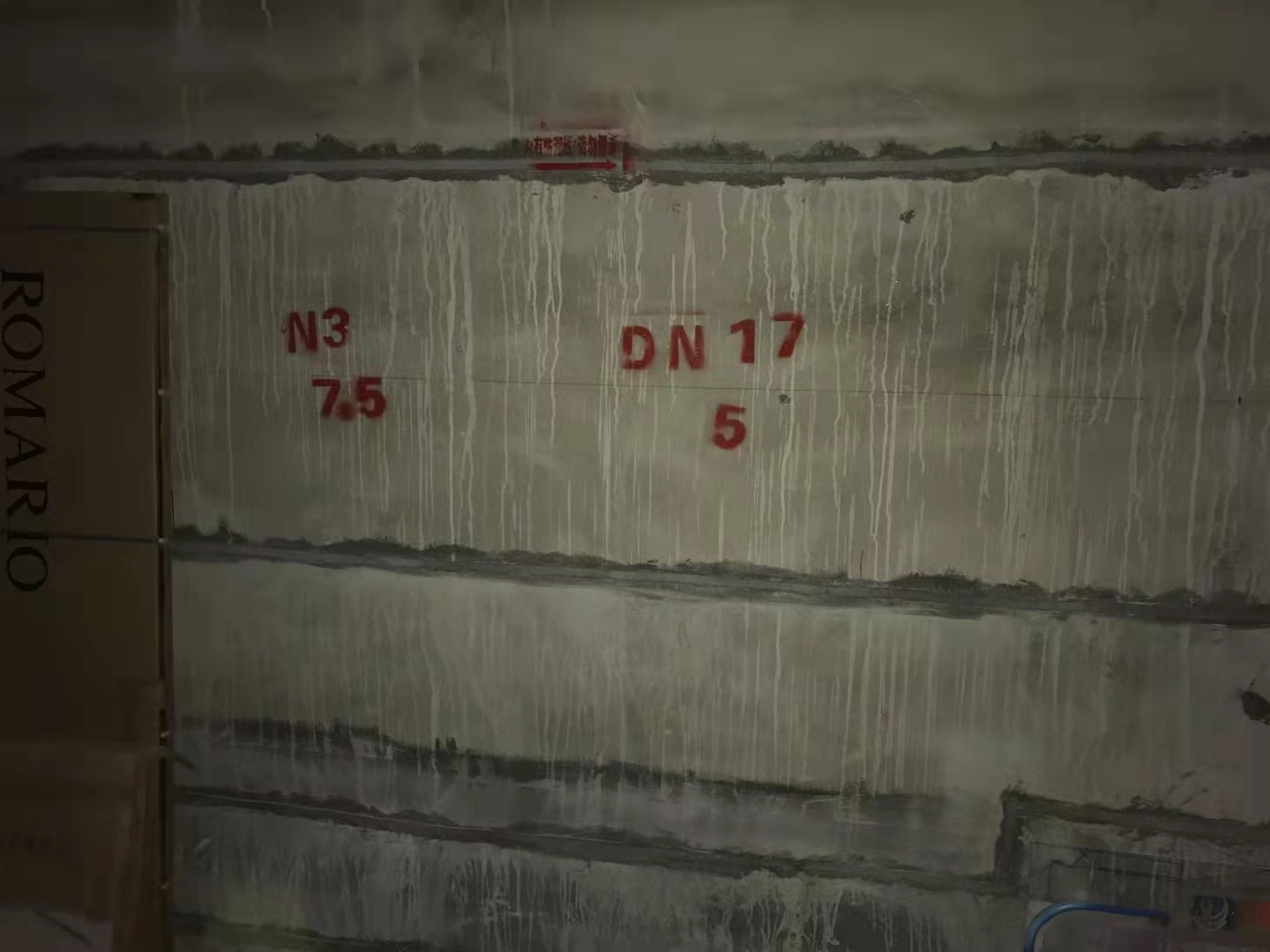

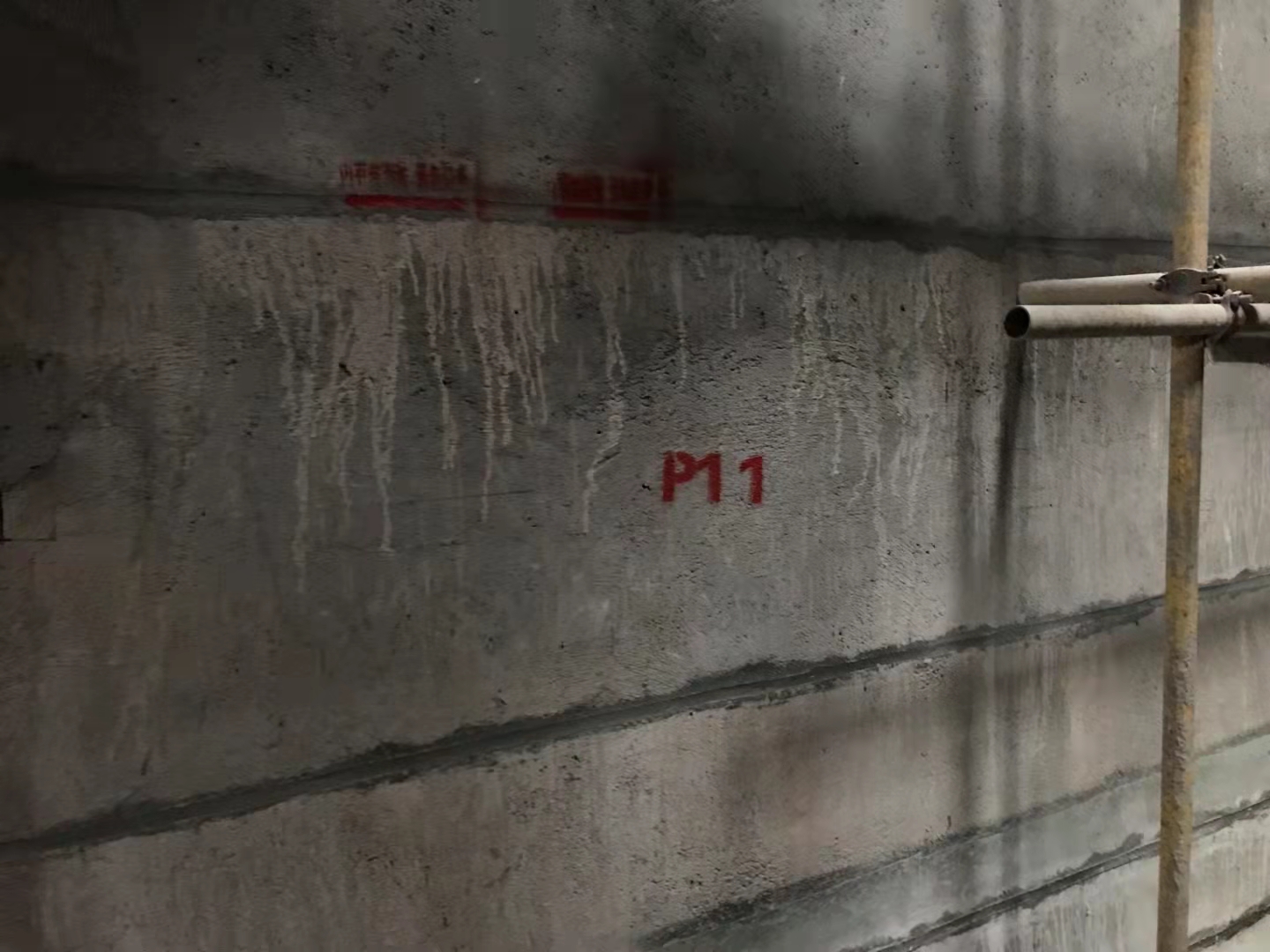

△Our water cutting site△

I believe you see this, must be very difficult to understand: powder grooving is obviously more advantageous, why do you still insist on water to cut?

The slotting pattern that was "hated,"

It's our armor!

Those who spend all day at the construction site must be deeply aware of the fact that "snow flying all over the sky" has become the norm at the construction site using powder.

And these powder dust is inhaled by the human body, causing damage is absolutely irreversible. Among the victims is the construction side, is our small partners in the engineering department. They often spend the whole day in the basement during the project. The basement environment is already stuffy compared to the ground, and the long hours of high-pressure work make their health "worse".

The reason why we insist on choosing "water slotting" wet operation is to make the working environment of the engineering department's partners relatively more comfortable. After all, the beautiful lines made by powder cutting are far less important than the state of an employee's work.

The "dirty" construction environment is temporary and can be restored when the project comes to an end. The protection of staff health is the real need to pay attention to.

As a business, we need to be loyal to our customers, but also to our employees who choose to believe in themselves. As Tongqiang consistently emphasizes "win-win" : win-win with customers to achieve product value; Win-win with employees to achieve common development.

How to implement the values of mutual help and trust? There's a long way to go... They are our pride, but they also need us to guard them -- we feel honored to put armor on them.

△Water cutting groove site△

△Water cutting groove site△

△Water cutting grooves advantage△

△Water cutting grooves advantage△